OEM Quality Parts, Assemblies and Maintenance

for Military Track and Wheeled Vehicles

Worldwide.

Apex Defense Systems provides OEM quality parts and assemblies and maintenance and maintenance training for older legacy military equipment. A growing percentage of numerous military fleets around the world consist of older model military vehicles. These vehicles provide valuable and essential defense operations when they are properly maintained with parts matching or exceeding the Original Equipment Manufacturer’s specifications.

As OEMs stopped providing parts for legacy vehicles, the defense market has been inundated with low quality parts and assemblies manufactured by companies looking to capitalize on the military parts market. These low-quality parts lack the durability to perform as required in harsh military environments and require frequent replacement. More importantly, they endanger the lives of the soldiers relying on the operations and function of the equipment and lower the ability of the national defense to effectively respond to threats.

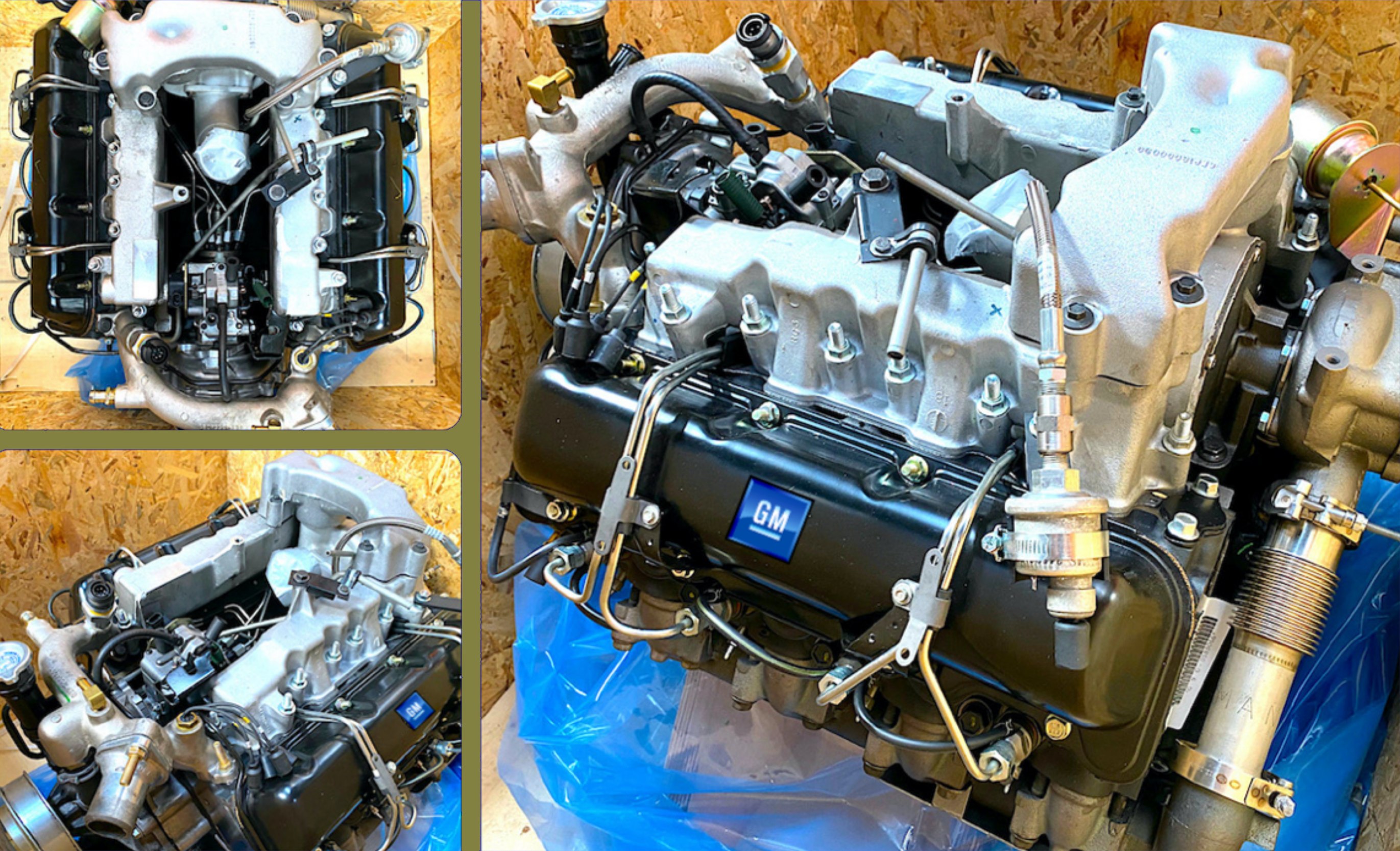

Apex Defense Systems supplies military replacement parts operating at or above the specifications of the original OEM parts. We have secured our own tank tread forging and vulcanizing operations for the manufacture of high-quality track shoe assemblies. We have our own engine and drive train manufacturing assembly line to ensure high quality reliable drive trains that perform as specified. We have contracted relationships with over 25 manufacturers who produce all products to our specifications.

Apex Defense Systems ensures militaries have the right parts and maintenance capabilities to maintain their equipment to defend its people.

Apex Defense Systems provides in-country maintenance and training programs including:

● Commercial, Tactical and Combat Vehicle Maintenance, Repair, and Refurbishment

● Vehicle and Equipment Operator and Maintainer Training Programs

● Providing Field Service Representatives (FSRs)

● Supply Operations, Inventory Control, and Property Management

● Parts Kitting, Packaging, Warehousing Operations and Care of Supplies in Storage

● Forward Operating Base Support

● Applying Modification Work Orders and Engineering Changes

● Licensed Defense Trade Export Broker & Manufacture/Exporter

● Process Improvement (LEAN)

● Consulting, Training and Auditing for ISO 9001 (Quality), 20000-1 (IT Service) & 27001 (InfoSec)

● HMMWV (All Variations)

● MRAP (All Variations)

● FMTV (Family of Medium Tactical Vehicles)

● HEMTT 8x8 (All Variations)

● M35 Series 2 ½ Ton (A2 & A3)

● M52, M800 and M900 Series 5 ton (A1 & A2)

● M60, M88 and M48 Tanks (All Variations)

● M113 / YPR – Armored Personal Carrier (All Variations)

● M109, M119 Howitzer (All Variations)

● M2 / M3 Bradley Fighting Vehicle

● M1117 / V150 Series (All Variations)

● M1 Abram (Main Battle Tank)

● All M-Series Trailers of any size, including Patriot

● M915 Thru M920 Series (A1 & A2)

● SEE (Small Enhancement Excavator)

● Various Engineer Equipment – 950B, 130G, etc.

● 4K, 6k, 10K Forklifts

● All Generators / Power Units

● M9ACE

Additional Systems by request

● Group 01 Engine (Drivetrain)

● Group 03 Fuel System

● Group 04 & 05 Exhaust and Cooling Systems

● Group 06 Electrical Systems

● Group 07 & 08 Transmission / Transfer / Final Drive

● Group 09 Propellor Drive Shafts / U-Joints

● Group 10 & 11 Front & Rear Axels

● Group 12 Braking Systems

● Group 13 Wheels / Tires / Tracks

● Group 14 Steering System

● Group 15 & 21 Frame / Towing / Bumper / Guards / Fenders

● Group 16 Springs / Shocks / Suspension Systems

● Group 18 & 22 Body / Cab / Hood / Chassis / Acc. (Mirrors)

● Group 47 Gauges / Weighing / Measuring Devices

● Group 52 Heating / AC / Refrigeration Components

● Group 94 Repairs Parts Kits

Miscellaneous Turret Systems / Bearings / Filters / Hardwear